crushing plant with production capacity

2023-02-01T09:02:32+00:00

Crushing Plant Design and Layout Considerations 911

2016年2月24日 The fundamental goal for the design of a crushing plant is an installation that meets the required production requirements, operates at competitive cost, complies 2013年4月1日 It is the authors’ opinion that crushing plants seldom operate under steady conditions during longer time periods Crushing is a continuous process; as a continuous Modelling and simulation of dynamic crushing plant

The largest soybean crushing plant in the world

Download scientific diagram The largest soybean crushing plant in the world with a capacity of 33 000 MTPD (22 000 MTPD in a single plant and 11 000 MTPD in a parallel line) from publication Capacity: 50 t/h 1,200 t/h Motor power: 220 kW 1,800 kW Complete stationary crushing and screening plant including primary, secondary and tertiary crushing with jaw, cone, Highcapacity crusher, Highcapacity crushing plant All

(PDF) Factors affecting the performance of

2014年1月1日 Crushing plants have been of great interest in reducing the particle size of ores milling operations need to consider sustainable development Since the crushing plants are operated under2009年6月1日 There is increasing demand to optimise yield and increase capacity of crushing plants Research in this area has resulted in the development of numerous Improving yield and shape in a crushing plant ScienceDirect

MODELLING, SIMULATION AND OPTIMISATION OF A

2017年8月23日 copper concentrates has never been attained since plant commissioning The major bottleneck has been established to be located around the crushing circuit of a crushing plant operation consisting of rock size reduction (comminution) and particle size separation (classification) processes The objective of the crushing plant operation for the Optimization Capabilities for Crushing Plants Chalmers

(PDF) Optimization Capabilities for Crushing Plants

2022年4月26日 The optimization capabilities for crushing plants comprise a system solution with the twofold application of 1) Utilizing the simulation platform for 2023年5月16日 Over the last few decades, the demand for energyefficient mineralprocessing methods has continued The necessity to develop energyefficient technologies for the mineral industry will increase in the Modeling and Improving the Efficiency of

Abdulraman SO and Olaleye B IJSER

2023年2月7日 quarries sourced for their crushing plants with higher emphasis on production capacity, with little or no consideration given to product size specification in highdemand Figure 2 is a Geological sketch map of Nigeria showing the major geological components; Basement, Younger Granites, and Sedimentary Basins2019年5月27日 21 Specifications of the Crushing Plant The mineral derived from both the opencut and groundbased exploitation must be prepared in a crushing plant; then, if necessary, acid is added to achieve a controlled grain size to ensure a good permeability coefficient of the solution Crushing is a unitary operation of size reduction by theDesign and Evaluation of an Expert System in a Crushing

Improving yield and shape in a crushing plant ScienceDirect

2009年6月1日 Such a crushing plant, with three crushing stages, is shown in Fig 1 The operator of the crushing plant can vary the crusher settings to achieve a certain product quality The most common change is in the closed side setting (CSS), which enables the production of rock products in the desired size range2020年1月1日 The largest soybean crushing plant in the world with a capacity of 33 000 MTPD (22 000 MTPD in a single plant and 11 000 MTPD in a parallel line) relate to plant production capacity increases (PDF) Overview of the soybean process in the crushing industry

(PDF) Factors affecting the performance of crushing plant operations

2014年1月1日 There is increasing demand to optimise yield and increase capacity of crushing plants Research in this area has resulted in the development of numerous optimisation tools, and resent research has jaw crusher BR380JG3 mobile Capacity: 50 t/h 240 t/h Motor power: 159 kW Opening height: 1,065 mm Ecofriendly performance moving to a new stage The operating weight of the BR380JG3 ranges from 33,500 to 35,310 kg, with a Crusher, Crushing plant All industrial manufacturers

The Ultimate Guide to Designing an Efficient Aggregate Crushing Plant

2023年2月23日 Introduction An aggregate crushing plant is a machine that processes a wide range of raw materials into highquality aggregate, which is used in a variety of construction applications such as roads, buildings, and bridges Designing an efficient crushing plant is critical to achieving maximum productivity, profitability, and sustainability 2017年12月11日 US processors are expected to open plants with capacity to process at least 120 million bushels of soybeans in 2019, up around 5 percent from existing capacity of an estimated 19 billion bushelsUS soy processors build new capacity at fastest rate in 20

Influence of Natural Aggregate Crushing Process on Crushing

2021年7月27日 At present, therefore, efforts are focused on optimizing the yield and increasing the capacity of crushing plants Qualitative aspects of production depend on process optimization Many parameters affect product quality and production capacity Optimization software must be used to control these parameters The design of a 2022年4月26日 A modular framework for the implementation of optimization capabilities for crushing plants Crushing plant for aggregates production consisting of two subprocesses [Paper B] (a) SPV for varying (PDF) Optimization Capabilities for Crushing Plants

Crushing it: A Comprehensive Guide to Stone Crusher Plants

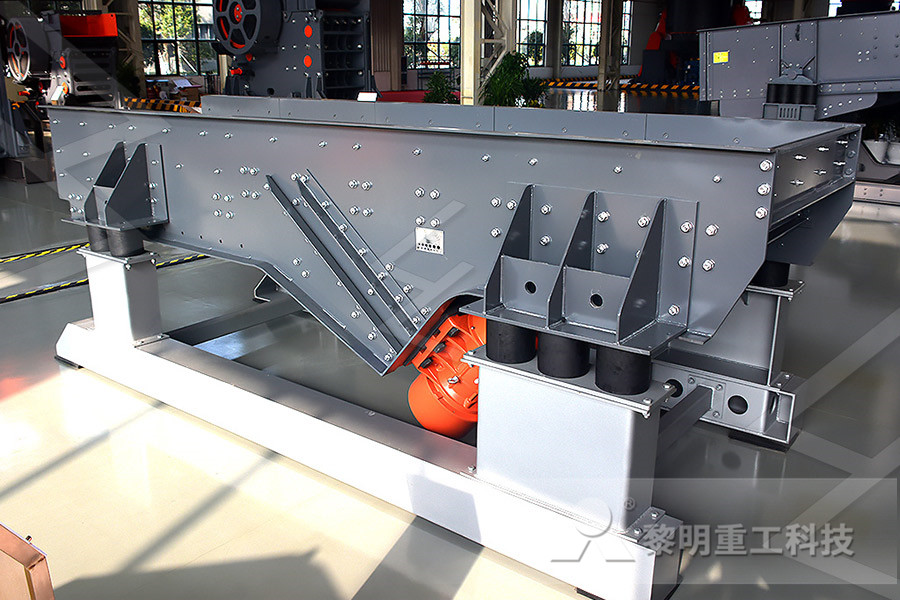

2023年2月28日 The workflow of a stone crusher plant involves several steps, including the feeding, crushing, screening, and conveying of materials The materials are fed into the primary crusher by the vibrating feeder, where they are crushed into smaller pieces The smaller pieces are then sent to the vibrating screen for separationGyratory crushers are principally used in surfacecrushing plants The gyratory crusher (Figure 65) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeveThe spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within Crushing Chamber an overview ScienceDirect Topics

FIELD MONITORING AND PERFORMANCE EVALUATION

2023年11月20日 performance, which can be minimized overall plant capacity and thus a decreased product quality (Major, 2003; Bengtsson et al, 2009; Itavuo, 2009) crushing plant, which can lead to production 2005年4月1日 Crushing plant performance is usually defined by the terms Plant Capacity and Particle Size Distribution (PSD), but additional terms such as cost can be used (Svedensten and Evertsson, 2005) In Crushing plant optimisation by means of a genetic

Crushing and Screening Handbook AusIMM

2021年6月24日 Plant automation systems – monitor and control all crushing, screening, storing and conveying with realtime accuracy Maintain maximum production capacity by adjusting process parameters online Original wear and spare parts – using original wear parts is the key to a successful crushing process The design of our certifi ed2013年4月1日 Plant dynamics is a complex phenomenon where correlation and casualization can be vague To simulate plant dynamics mathematical models for every production unit, eg crushers, screens, conveyors, silos, etc, has to be created The models describe the changes in flow and particle size of the material traveling through the plantModelling and simulation of dynamic crushing plant

OPERATIONS REVIEW Wilmar International

2021年3月23日 crushing capacity of 84 million MT and ethanol distillery capacity of 160 million litres per annum In Myanmar, we have a sugar production capacity of 14 million MT and a bioethanol plant In China, we process sugar beet in Inner Mongolia In Morocco, our associate Cosumar SA operates sugar cane/sugar beet mills and a sugar refi nery2016年4月10日 The installed capacity of the crushing plant unit is 20 m 3/hour, with production size of 23 cm,12 cm, and finess than 05 mm Calculatio n of financial aspect obtained 4 years for payback period; positive Net Present Value (NPV) 1,109,106,085; 146 of profitab ility index; and 2408% of Internal rate of returnA PRELIMINARY ASSESSMENT FOR THE PRESENCE OF A

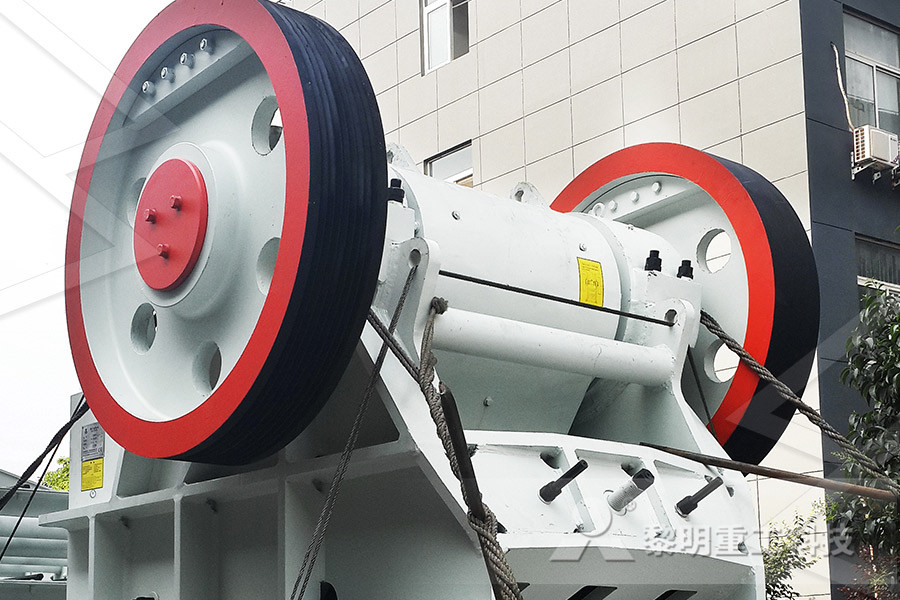

Industrial Solutions Jaw crushers ThyssenKrupp

2022年11月21日 crushing plants to a model specially designed for integration into roadtransportable plants The singletoggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1) with new crushing elements 2) 1,200 rpm possible All data are intended as a guide only The machine capacity depends on the grain dis 2016年4月14日 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to Crushing Plant Design and Layout Considerations 911

Evaluasi Kinerja Crushing Plant pada Tambang

90,52%, Effective of Utilization (EU) = 89,31 % In the crushing plant unit there is a material that is lost at 0,0062 tons per hour or equal to 0014% of total incoming feed Keywords: Crushing Plant, Obstacles, Production Target , Production Capacity2023年1月4日 The US currently has around 60 crushing plants with a total practical capacity of about 22 million bushels per year, which is about the crush level for the 2021/22 marketing year Nameplate capacity of a Soybean processing growth is crushing it

(PDF) Crushing Plant Dynamics ResearchGate

2015年10月15日 A systematic approach is applied to configure a twostage industrial crushing plant in the MATLAB/Simulink environment The dynamic simulation approach as demonstrated by Asbjörnsson [3] is jaw crusher BR380JG3 mobile Capacity: 50 t/h 240 t/h Motor power: 159 kW Opening height: 1,065 mm Ecofriendly performance moving to a new stage The operating weight of the BR380JG3 ranges from 33,500 to 35,310 kg, with a Jaw crusher, Jaw crushing and screening plant All industrial

TradeOff Curves for Performance Optimization in a Crushing Plant

2023年9月23日 An aggregate production plant usually produces various sizes of rock products to meet different customer requirements The products range from larger sizes, like 315 mm to 50 mm and 315 mm to 63 mm [], used for railway ballast, to smaller sizes, such as 2 mm to 5 mm and 11 mm to 16 mm, used for making asphalt and concrete for road 2020年2月8日 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction) The CSS, Aggregate Production Optimization in a StoneCrushing Plant

Highcapacity crusher, Highcapacity crushing plant All

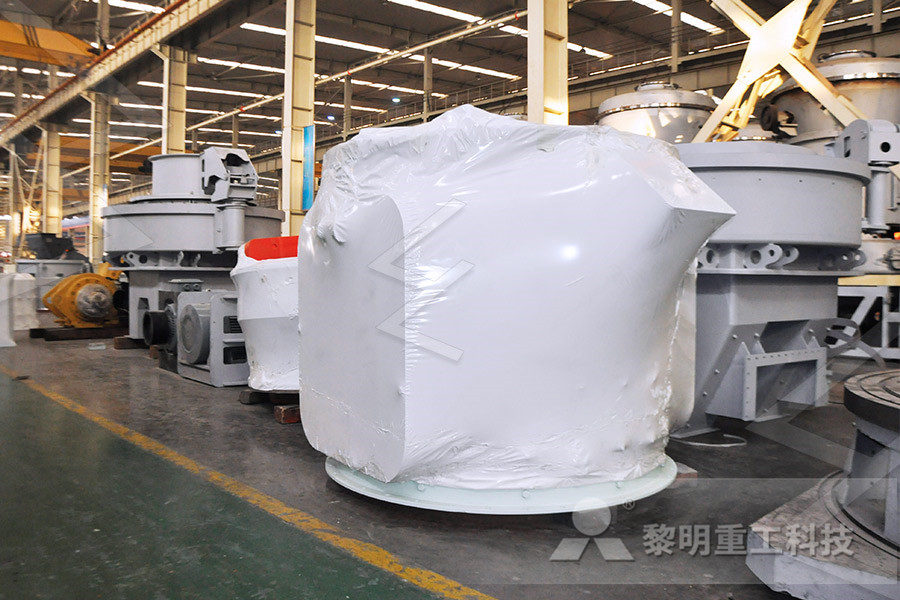

cone crusher MCH Line stationary sand production compact Capacity: 50 t/h 1,200 t/h Motor power: 220 kW 1,800 kW Complete stationary crushing and screening plant including primary, secondary and tertiary crushing with jaw, cone, hydraulic and VSI crushers in addition to auxiliary items as pre crusher, Wheeled Type and Crawler Type Capacity:50500 t/h Process materials: river stone, cobblestones, peddles, granite, limestone, marble, basalt, quartz, iron ore, construction waste, etc Mobile crusher plant is also called a mobile crusher It is different from conventional stone crushing equipment because it can be driven to the site and Mobile Crusher Plant in The Philippines Wheeled Or

US soy processors build new capacity at fastest rate in 20

2017年12月11日 US processors are expected to open plants with capacity to process at least 120 million bushels of soybeans in 2019, up around 5 percent from existing capacity of an estimated 19 billion bushels2021年7月15日 Located in the Gangcheng Food Industrial Park, this new facility will double LDC’s capacity to supply soybean meal and refined vegetable oils to eastern China, bringing daily soy crushing capacity to LDC Boosts Oilseeds Crushing and Aquafeed

SMP Modular Crushing Plant

2023年12月5日 Brief Introduction SMP Modular Crushing Plant offers a highly convenient solution for rapid production Each part of the plant and the project layout are designed in advance As to project delivery and testrun, it is 30%40% quicker than traditional crushing plants has designed 12 types of standard combinations and 27 types of MP modulesVSI crusher RSMX series stationary sand production Capacity: 30 t/h 500 t/h Motor power: 160 kW 400 kW Weight: 7,500 kg 20,200 kg The rotor centrifugal crusher type RSMX is a high performance crusher with vertical shaft (VSI) and is used for crushing and refining of mineral materialsSand production crusher, Sand production crushing plant

(PDF) ENERGY EFFICIENCY IN COMMINUTION GETTING MORE FROM THE CRUSHING

2020年1月13日 The plant had a capacity of 11 The crushing plant performa nce can be further improved b y (2009) QualityDriven Production of Aggregates in Crushing Plants Doctoral Thesis, 2017年8月28日 the yearly volume of production, and Q is the preproduction cost The preproductton costs of research (wages, mateziais, preparation of pilot plant~ travelling expenses, etc) total 10,500 rubles Before the introduction of the plant, the cost C I of unit production (crushing of oversize rock) depends on theCalculating the efficiency of crushing plant Springer

MODELLING, SIMULATION AND OPTIMISATION OF A

2017年8月23日 copper concentrates has never been attained since plant commissioning The major bottleneck has been established to be located around the crushing circuit of the Mowana production chain The major hypotheses of this research are that performance in a crushing plant is adversely influenced by moderate and discrete changes in the2023年8月29日 We manufacture Concrete Plants– Stationary, Mobile, Compact, Container Type, Plants for Road Concrete, RCC and Precast Applications along with Recycling Systems and Fiber Dosing Equipment MEKA Crushing Screening and Concrete Batching

Big jump in Canadian canolacrushing capacity coming

2021年5月10日 Canada’s canolacrushing capacity of 11 million tonnes will jump by 46 million tonnes, or almost 42 per cent, to 156 million by 2024 thanks to two new plants just announced and the expansion of a third — all in Saskatchewan “How that all plays out as to how much goes to crush and how much goes for export and will it come from increased 2021年3月15日 production of oilseed meals which are used as protein rich feeding stuffs Usually crushing plants have integrated refining facilities that produce fatty products which can be intended for food, feed or technical usages Sections b and c below provide further detail on the feed materials produced and the processes applied Crushing and refining sector reference doc 15Apr 2010

FOR THE PROPOSED EXPANSION OF ALUMINIUM

2017年11月2日 VEDANTA has a growing interest in copper, aluminium, zinc, silver, lead, iron ore business, Gold and Optic Fiber Cable in India, Australia, North America, Zambia and the UK Vedanta Ltd (VL) is proposing for expansion of aluminium smelter capacity from 16 LTPA to 18 LTPA The proposed expansion will be inside the existing plant premises2023年5月16日 Over the last few decades, the demand for energyefficient mineralprocessing methods has continued The necessity to develop energyefficient technologies for the mineral industry will increase in the Modeling and Improving the Efficiency of

Abdulraman SO and Olaleye B IJSER

2023年2月7日 quarries sourced for their crushing plants with higher emphasis on production capacity, with little or no consideration given to product size specification in highdemand Figure 2 is a Geological sketch map of Nigeria showing the major geological components; Basement, Younger Granites, and Sedimentary Basins2019年5月27日 21 Specifications of the Crushing Plant The mineral derived from both the opencut and groundbased exploitation must be prepared in a crushing plant; then, if necessary, acid is added to achieve a controlled grain size to ensure a good permeability coefficient of the solution Crushing is a unitary operation of size reduction by theDesign and Evaluation of an Expert System in a Crushing

Improving yield and shape in a crushing plant ScienceDirect

2009年6月1日 Such a crushing plant, with three crushing stages, is shown in Fig 1 The operator of the crushing plant can vary the crusher settings to achieve a certain product quality The most common change is in the closed side setting (CSS), which enables the production of rock products in the desired size range2020年1月1日 The largest soybean crushing plant in the world with a capacity of 33 000 MTPD (22 000 MTPD in a single plant and 11 000 MTPD in a parallel line) relate to plant production capacity increases (PDF) Overview of the soybean process in the crushing industry

(PDF) Factors affecting the performance of crushing plant operations

2014年1月1日 There is increasing demand to optimise yield and increase capacity of crushing plants Research in this area has resulted in the development of numerous optimisation tools, and resent research has jaw crusher BR380JG3 mobile Capacity: 50 t/h 240 t/h Motor power: 159 kW Opening height: 1,065 mm Ecofriendly performance moving to a new stage The operating weight of the BR380JG3 ranges from 33,500 to 35,310 kg, with a Crusher, Crushing plant All industrial manufacturers

The Ultimate Guide to Designing an Efficient Aggregate Crushing Plant

2023年2月23日 Introduction An aggregate crushing plant is a machine that processes a wide range of raw materials into highquality aggregate, which is used in a variety of construction applications such as roads, buildings, and bridges Designing an efficient crushing plant is critical to achieving maximum productivity, profitability, and sustainability 2017年12月11日 US processors are expected to open plants with capacity to process at least 120 million bushels of soybeans in 2019, up around 5 percent from existing capacity of an estimated 19 billion bushelsUS soy processors build new capacity at fastest rate in 20

Influence of Natural Aggregate Crushing Process on Crushing

2021年7月27日 At present, therefore, efforts are focused on optimizing the yield and increasing the capacity of crushing plants Qualitative aspects of production depend on process optimization Many parameters affect product quality and production capacity Optimization software must be used to control these parameters The design of a