cement cement grinding mill manufacturing

2022-06-26T02:06:47+00:00

Cement Mill Cement Grinding Machine AGICO

Cement mill also called cement grinding mill, is a cement grinding machine used in cement plant for raw materials, cement clinker, and coal grinding The cement mill produced by AGICO can be divided There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the Cement Extraction, Processing, Manufacturing Britannica

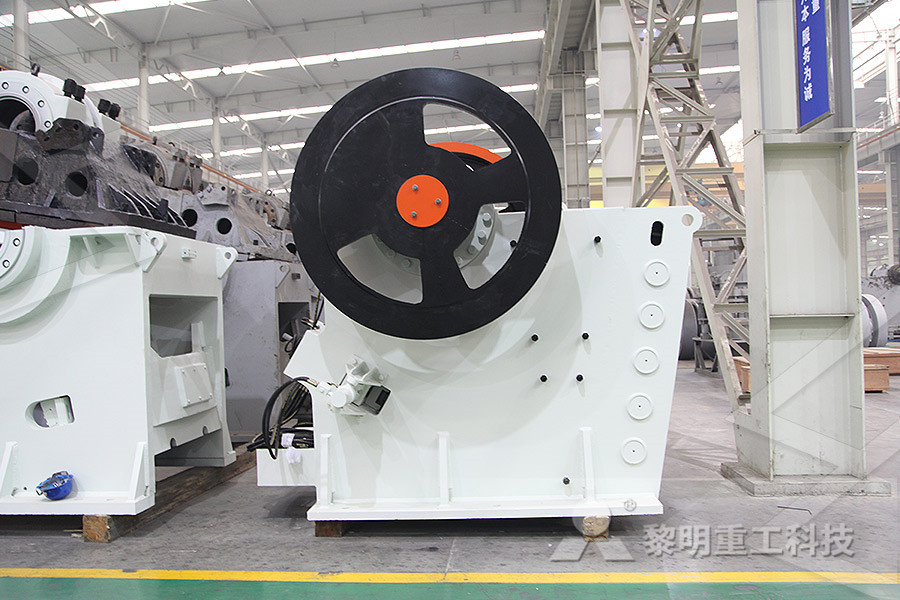

Ball Mill In Cement Plant Cement Ball Mill AGICO

AGICO Cement is a cement equipment manufacturer with more than 20 years’ experience We are the longterm partner of many large and mediumsized cement enterprises in different countries, providing cement The cement ball mill is a kind of cement grinding mill It is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric power Cement Ball Mill Cement Grinding Machine

116 Portland Cement Manufacturing US Environmental

Q Raw mill air seperator 26 R Finish grinding mill feed belt 27 S Finish grinding mill weight hopper 28 T Finish grinding mill air seperator 29 U Preheater kiln 30500622 V Preheater/Precalciner kiln 30500623 The second step in portland cement manufacture is preparing the raw mix, or kiln feed, for theThere are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as “ clinker ,” together with some 5 percent of gypsum (to control the time of set of the cement)Cement Extraction, Processing, Manufacturing Britannica

116 Portland Cement Manufacturing US Environmental

Q Raw mill air seperator 26 R Finish grinding mill feed belt 27 S Finish grinding mill weight hopper 28 T Finish grinding mill air seperator 29 U Preheater kiln 30500622 V Preheater/Precalciner kiln 30500623 The second step in portland cement manufacture is preparing the raw mix, or kiln feed, for the2023年10月19日 The installation of a fifth vertical cement grinding mill will enhance processing and allow cement production capacity to increase while reducing net CO2 emissions by more than 400,000 tons per yearHolcim US Flagship Cement Plant to Accelerate Decarbonization

Cement Ball Mill Cost Effective Cement Grinding Mill from AGICO

AGICO cement ball mills have a wide range of models, with a maximum output of 130 tons per hour, which can meet the production needs of large, medium, and small cement manufacturers Based on the grinding system used by customers, we can customize and optimize the ball mill Whether it is an opencircuit grinding system, a closedcircuit Cement Grinding: cement grinding is the final stage in Portland cement manufacturing In this step, clinker will be ground in grinding mill to reach the qualified fineness of cement product During the grinding, we usually add gypsum, fly ash and other raw materials into the cement to realize the different usage of cementPortland Cement Manufacturing Process In Cement Plant AGICO

Cement Finish Milling (Part 1: Introduction History)

2019年12月2日 The finish mill system in cement manufacturing is the second to last major stage in the process, However, the history of cement grinding is incomplete without looking back to the 1930’sThe polysius® booster mill, a dry agitated bead mill, has been in development by a cooperation between Netzsch Feinmahltechnik and thyssenkrupp for several years, with the original target application in very fine cement grinding However, trials and an industrialsize pilot installation turned out to meet a far broader range of interesting polysius® booster mill

Cement grinding optimisation ScienceDirect

2004年11月1日 grinding the cement clinker nodules to 100% passing 90 μm in a dry circuit Grinding occurs at the beginning and the end of the cement making process Approximately 15 tonnes of raw materials are required to produce 1 tonne of finished cement The electrical energy consumed in the cement making process is in order of Q Raw mill air seperator 26 R Finish grinding mill feed belt 27 S Finish grinding mill weight hopper 28 T Finish grinding mill air seperator 29 U Preheater kiln 30500622 V Preheater/Precalciner kiln 30500623 The second step in portland cement manufacture is preparing the raw mix, or kiln feed, for the116 Portland Cement Manufacturing US Environmental

Mini Cement Plant EPC Cement Line Capacity 70 600 TPD

Mini Cement Plant Features Cement plants with a clinker capacity below 700tpd can be called mini cement plants or small cement plants Mini cement plants are very popular among small and mediumscale cement manufacturing enterprises since they do not require very large cement production capacities Because of their small output 2012年8月30日 Cement Manufacturing Process Phase 1: Raw Material Extraction Cement uses raw materials that cover calcium, silicon, iron and aluminum Such raw materials are limestone, clay and sand Limestone is for calcium It is combined with much smaller proportions of sand and clay Sand clay fulfill the need of silicon, iron and Cement Manufacturing Process Phases Flow Chart Cement

How to Make Your Cement Grinding Plant More Energy Saving?

Its power consumption accounts for 65% – 75% of the whole cement plant Therefore, reducing the energy consumption in the cement grinding process is of great significance for energy conservation and emission reduction of the cement manufacturing plant At present, some small and mediumsized cement plants still adopt traditional cement ball Based on customer needs and years of experience in cement equipment manufacturing, AGICO Cement develops a lowcost and high efficient EPC solution for cement grinding unit – modular mobile (MMG) cement grinding plant Compared to the traditional grinding station available on the market, the MMG cement grinding plant is more Modular Mobile Cement Grinding Plant For Sale AGICO Cement

AN INTRODUCTION TO THE CEMENT MANUFACTURING

2023年11月4日 Module 4: Cement Grinding Systems and Dispatch Cement clinker is grinding in roller mills and ball mills, such as granulated blast furnace slag, fly ash, limestone, and approximately 5% sulfate agents (eg, gypsum) During production and before leaving the plant, the cement is internally inspected and tested in the plant’s 2023年7月10日 The cement manufacturing process involves the extraction and processing of raw materials, such as limestone, clay, and shale, which are then heated in a kiln at high temperatures to form clinker Cement Manufacturing Process and Its Environmental Impact

Cement Manufacturing Machine Cement Making Machine Cement

Choose the right cement manufacturing machine is an important influence factor to produce highquality cement It saves 30% – 40% energy consumption compared with the ball mill grinding system Cement Ball Mill Cement ball mill is a kind of horizontal cylindrical rotary grinding device Through a continuous rotation, Ball Mill The proven classical option for cement grinding Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding Used in combination with the sepol ball mill thyssenkrupp Polysius

Portland Pozzolana Cement Manufacturing Cement

Portland pozzolana cement shall be manufactured by mixing and intergrinding Portland cement clinker, pozzolanic materials, and gypsum The manufacturing process is approximately the same as ordinary Portland 2021年8月28日 Distribution of dust emissions at bag filters in the cement mill section no1 (mill filterpoint A and separator filterpoint B, Figure 1) of the analyzed cement plant(PDF) Dust Emission Monitoring in Cement Plant Mills: A

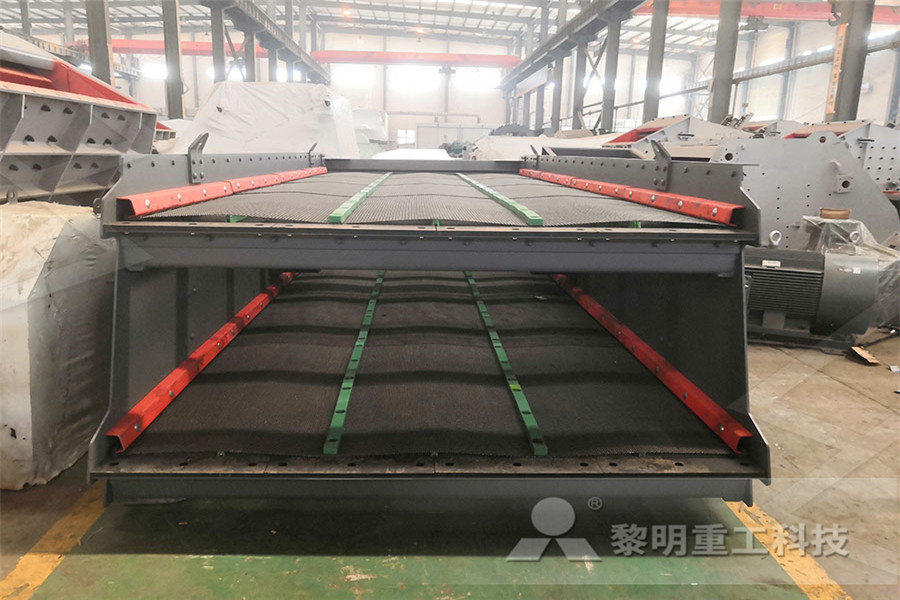

Cement Plant Equipment Cement Crusher, Cement Mill, Cement

2019年11月21日 Cement ball mill Cement ball mill is core equipment for cement grinding It has own advantages in operation, application, and structure, at present, cement ball mill has widest applications High working efficiency, the cement ball mill produce uniform particles, increases the production capacity by 25%cement ball mill Application: limestone, clay, coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag Capacity: 065615T/H The cement ball mill usually can be applied to raw meal grinding or cement grinding Besides, the cement ball mill also can be used for metallurgical, chemical, electric power, other mining Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant Cement

CEMENT TRAINING COURSES The Cement Institute

The Cement Institute’s training programs are adequate solutions designed to address the specific challenges of clients’ sites: – Effective Communication: We work collectively to create and prepare what topics and areas are to be covered, set the target goal, and pinpoint areas of needed improvements – Critical Thinking: Looks at the It has been established that about 7–10% of the cement can be lost due to uncontrolled emissions in the cement mill [ 21 ] Some studies show that 4–5% of dust emissions are due to the furnace’s supply, while other dust emission sources are crushers, clinker coolers, grinding, and material handling equipment [ 35 ]IJERPH Free FullText Dust Emission Monitoring in Cement Plant

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc In another word, the cement grinding mill can increase the cement quality and guarantee the qualification rate of cement In general, cement mill can both apply for dry cement production and wet cement production Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement millCement Mill Cement Ball Mill Vertical Cement Mill AGICO

Production Process CEMEX Philippines

There are two primary processes used to manufacture clinker: the dry process and the wet process Our plants use the dry process, which is more energy efficient In the wet process, the raw materials are mixed with water to form slurry, which is fed into a kiln Fuel costs are greater in the wet process than in the dry process because the water The fly ash processing plant produced by AGICO includes a ball mill grinding system, conveying system, dust collecting system, ash classifying system and ash storing system It helps our customers realize reasonable solid waste recycling and utilizationFly Ash Processing Plant Cement Equipment Manufacturing

Cement Mill for Sale Buy Cement Ball Mill Vertical Roller Mill

Cement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the main types of cement mill we produce As a professional cement equipment manufacturer, AGICO has rich 2022年12月1日 Cement powder obtained from the grinding mill is then taken to the packing plant for packaging and dispatch (Cembureau, 1997; ACC, 2015; Lakshmikanth, 2011) Fig 1 shows the sequence of processes during the manufacturing of cementReview on energy conservation and emission reduction

(PDF) The Effect of Various Grinding Aids on the

2022年1月14日 production of Portland cement, grinding aids are added in small amounts in the range of 001 to 010% by weight of cement, according to the PNEN 1971 standard [ 1A thermocouple is a device made by two different wires joined at one end, called the junction end, or measuring end The two wires are called thermoelements or legs of the thermocouple The other AIR POLLUTION CONTROL TECHNIQUES FOR THE CEMENT MANUFACTURING INDUSTRY

Modeling of energy consumption factors for an industrial cement

2022年5月9日 Lin, X Liang, J Modeling based on the extreme learning machine for raw cement mill grinding process in Proceedings of the 2015 Chinese Intelligent Automation Conference 129–138 (2015)The new dryprocess of cement manufacturing technology makes good use of the limestone resources discarded in the traditional mining method and applies the pre decomposition technology, suspension preheating technology, and multichannel burner to reuse the recycled and lowquality fuels Besides, it effectively reduces the emission of Dry Process Of Cement Manufacturing Dry Cement AGICO

Grinding process is a critical stage in cement production

2023年8月21日 In Udaipur Cement Works Limited, we use the following types of mills for grinding raw materials and cement: • Vertical Roller Mill (VRM): We employ the Loesche (LM 384) and Gebr Pfeiffer (MVR 6000C6) technology for raw material and cement grinding respectivelyIn white cement plants, the main manufacturing process includes six steps: raw material crushing, raw material grinding, clinker calcination, clinker cooling, cement grinding, and cement packing AGICO provides white cement plant EPC projects with a daily capacity of 100 to 10000 tons 1White Cement Manufacturing – White Cement Plant AGICO Cement

Cement Manufacturing Process Wet and Dry Processes

2023年6月14日 Cement manufacturing is an intricate process involving the extraction and grinding of raw materials, followed by blending and heating in a kiln to produce clinker This clinker is then ground with gypsum to create cement, a vital component for construction However, the process is energyintensive and contributes to environmental challenges Microsoft Word IOP 287 Praveen Purshottaaim Parieek IOP Conference Series: Materials Science and Engineering PAPER • OPEN ACCESS Increase productivity of vertical roller mill using seven QC tools To cite this article: Praveen Pareek and Dr Vijayendra Singh Sankhla 2021 IOP Conf Ser: Mater Sci Eng 1017 Indicate Contributions from Several Radial VHYHQ4WRROV

Ball Mill In Cement Plant Cement Ball Mill AGICO

AGICO Cement is a cement equipment manufacturer with more than 20 years’ experience We are the longterm partner of many large and mediumsized cement enterprises in different countries, providing cement The cement ball mill is a kind of cement grinding mill It is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric power Cement Ball Mill Cement Grinding Machine

116 Portland Cement Manufacturing US Environmental

Q Raw mill air seperator 26 R Finish grinding mill feed belt 27 S Finish grinding mill weight hopper 28 T Finish grinding mill air seperator 29 U Preheater kiln 30500622 V Preheater/Precalciner kiln 30500623 The second step in portland cement manufacture is preparing the raw mix, or kiln feed, for theThere are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as “ clinker ,” together with some 5 percent of gypsum (to control the time of set of the cement)Cement Extraction, Processing, Manufacturing Britannica

116 Portland Cement Manufacturing US Environmental

Q Raw mill air seperator 26 R Finish grinding mill feed belt 27 S Finish grinding mill weight hopper 28 T Finish grinding mill air seperator 29 U Preheater kiln 30500622 V Preheater/Precalciner kiln 30500623 The second step in portland cement manufacture is preparing the raw mix, or kiln feed, for the2023年10月19日 The installation of a fifth vertical cement grinding mill will enhance processing and allow cement production capacity to increase while reducing net CO2 emissions by more than 400,000 tons per yearHolcim US Flagship Cement Plant to Accelerate Decarbonization

Cement Ball Mill Cost Effective Cement Grinding Mill from AGICO

AGICO cement ball mills have a wide range of models, with a maximum output of 130 tons per hour, which can meet the production needs of large, medium, and small cement manufacturers Based on the grinding system used by customers, we can customize and optimize the ball mill Whether it is an opencircuit grinding system, a closedcircuit Cement Grinding: cement grinding is the final stage in Portland cement manufacturing In this step, clinker will be ground in grinding mill to reach the qualified fineness of cement product During the grinding, we usually add gypsum, fly ash and other raw materials into the cement to realize the different usage of cementPortland Cement Manufacturing Process In Cement Plant AGICO

Cement Finish Milling (Part 1: Introduction History)

2019年12月2日 The finish mill system in cement manufacturing is the second to last major stage in the process, However, the history of cement grinding is incomplete without looking back to the 1930’sThe polysius® booster mill, a dry agitated bead mill, has been in development by a cooperation between Netzsch Feinmahltechnik and thyssenkrupp for several years, with the original target application in very fine cement grinding However, trials and an industrialsize pilot installation turned out to meet a far broader range of interesting polysius® booster mill